Sealing fluids

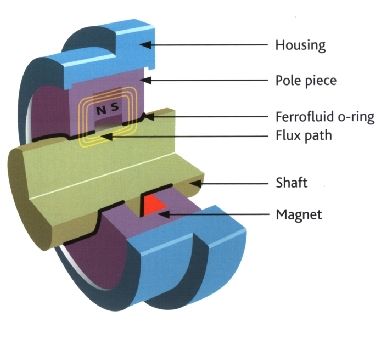

Role of Ferrofluid in a Seal

Traditional labyrinth rotary seals require constant maintenance to perform at an optimum level. They are also subject to wear and accumulation of particulate material, which can compromise the performance of a seal.

By the use of a ferrofluid to act as a magnetic O-ring and used in conjunction with traditional labyrinth seals, a rotary seal is produced where the shaft of the seal provides hermetic sealing with zero leakage.

Smart Seal Magnetic Circuit

Due to the magnetic nature of the ferrofluid seal, foreign particles are actually expelled from the system rather than accumulated.

As the ferrofluid consists of a high quality lubricating oil there is minimal wear. Where a large pressure differential is required, ferrofluid based seals typically give a burst pressure of several atmospheres.Ultimate burst pressure is governed by the number of stages in the seal.

Other sealing applications include the use of ferrofluid to seal hard disk drives. Liquids Research Limited have a proven track record in providing high quality ferrofluids for vacuum and non vacuum sealing applications. We manufacture fluids of high colloidal stability in a variety of carrier liquids, including synthetic oils and in perfluoropolyethers (PFPE) for use in hostile environments.

VacuMAG™ Fluid Specifications

Fluids with saturation magnetisation of up to 600 Gauss and greater can be produced with viscosities between 1000 cP and 25000 cP. See below for details.

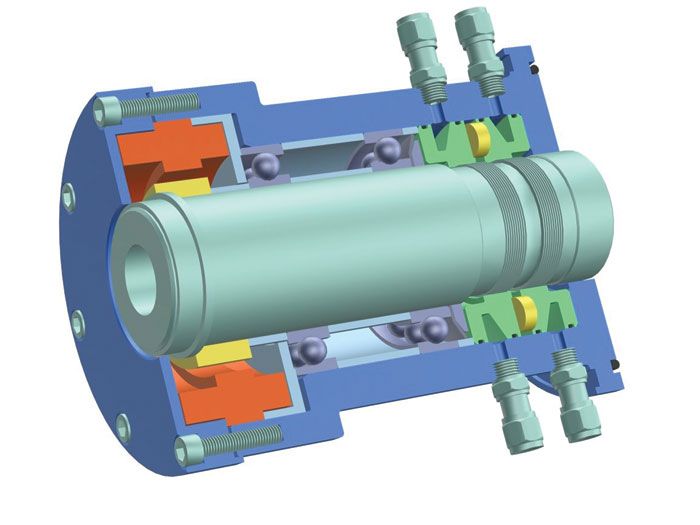

Typical heavy duty seals

Typical heavy duty seals

Typical 10mm diameter seal

The DRIVETHRU

| Ms | Viscosity | Vapour Pressure order of magnitude at 20°C | ||

|---|---|---|---|---|

| (Gauss) | (cP) | (Torr) | (Pa) | |

| F9 | 450 | 5000 | 10-9 | 10-7 |

| F11 | 400 | 10,000 | 10-11 | 10-9 |

| F13 | 400 | 20,000 | 10-13 | 10-11 |

| F16 | 400 | <25,000 | 10-16 | 10-14 |

| Ms | Viscosity | Vapour Pressure order of magnitude at 20°C (Torr) | ||

|---|---|---|---|---|

| (Gauss) | (cP) | (Torr) | (Pa) | |

| H9A | 600 | 1200 | 10-9 | 10-7 |

| H9B | 400 | 2000 | 10-9 | 10-7 |

| H9 | 300 | <1000 | 10-9 | 10-7 |

| Ms | Viscosity | Vapour Pressure order of magnitude at 20°C | ||

|---|---|---|---|---|

| (Gauss) | (cP) | (Torr) | (Pa) | |

| H9-LT | 400 | 300 | 10-9 | 10-7 |

Unless otherwise stated all viscosity values are ±15% and Ms values are ± 5% of the quoted values.

Viscosity measured at 27°C.

For further information on the use of vacuum sealing fluid click here.

Specifications subject to change without notice.